bonertifan1985.netlify.com

Slot Die Coater Design

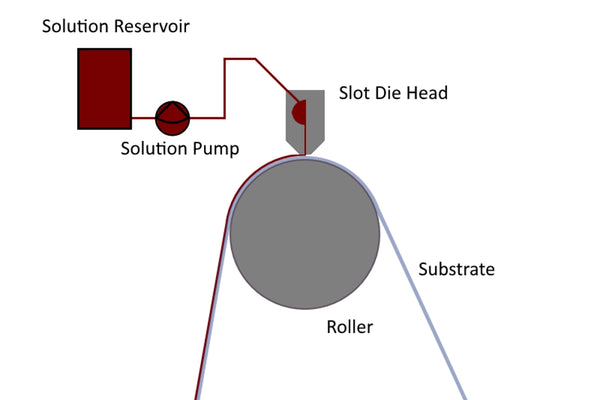

In the world of slot die coating, thin is in. Or, to be precise, thin AND accurate is in. According to Scott Zwierlein of Frontier, “roll-to-roll slot die coating has become the industry standard for extremely thin and extremely accurate coating.” Let’s take a look to see if it’s the right coating method for you.

“The use of slot die coating will increase because it has several advantages,” adds coating industry guru Dr. Edward Cohen. These include attributes such as excellent quality and uniformity, and the fact that it’s pre-metered so that all of the coating is applied to the substrate.

However, Cohen also notes that each converter has their own specific needs which will determine which coating methods should be used. So how do you determine if slot die is the coating method of choice for you?

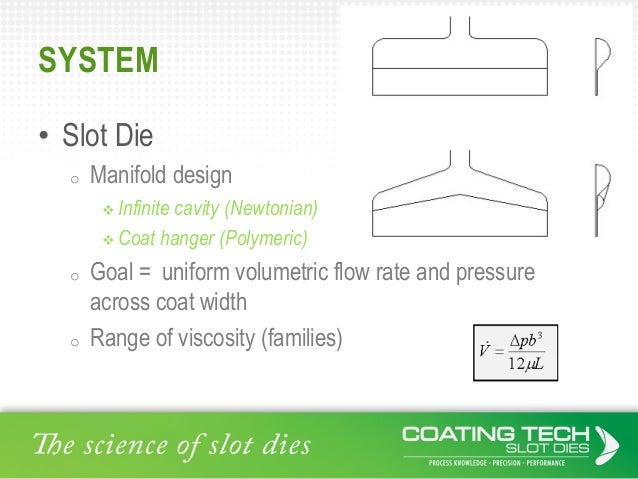

Inorder to realize the accuracy of tungsten carbide lip coater,Mitsubishi Materilas Corp. Supplies Rental Slot Die Coater.http://wrt.mitsubishicarbide.com/mm. As the first case, flow behaviors inside the slot die have been theoretically examined by three-dimensional (3-D) Fluent simulation. Effect of internal die design on the cross-web uniformity of coating liquids, both Newtonian and shear thinning liquids, at the slot die exit has been analyzed.

Let’s take an in-depth look at the technology and the uses to find the answer. (Full disclosure – Scott and Frontier are a subsidiary of Delta ModTech.)

How Thin is Thin and How Accurate is Accurate?

The fields of electronics, medical devices and pharmaceuticals continue to push the envelope, or should we say, the tolerances required for converters. At some point, their needs have exceeded the capabilities of traditional extrusion dies, and entered into the realm of the nearly infinitesimal.

Slot die coating can meet these new thickness and accuracy requirements. Just how thin can slot die go? With a slot die, Zwierlein explains you can achieve an attainable wet coating thickness of <2 micron. (NOTE: Slot die can be used to coat thick as well — we’re just highlighting the thin capabilities in this post.)

To put that in perspective, a “micron,” which is the abbreviated term for “micrometers,” is one millionth of a metre (or one thousandth of a millimetre, 0.001 mm, or about 0.000039 inch). A human hair is about 75 microns across.

Here’s a picture of a carbon filament 6 microns in diameter, overlaid on a human hair 50 microns in diameter.

Photo of a carbon filament, 6 microns in diameter, overlaid on a human hair, 50 microns in diameter. – Micro photo courtesy of Wikipedia.com

And how accurate is accurate? Accuracy in the coating world is flatness. Or, in other words, how much the thickness varies from your target. The attainable transverse web accuracy with a slot die is <2%.

Talk about little margin for error.

Now listen to this short audio interview with Scott Zwierlein, and then read on how slot die delivers on thin and accurate:

https://deltamodtech.com/wp-content/uploads/2016/12/Scott-Zwierlein.mp3

1. Extremely Thin

As Zwierlein notes, 2 microns is the “Holy Grail of liquid coatings.” Many traditional methods exist, but only slot die can achieve this level.

Why? It’s the nature of the equipment design. Other methods will flood a large amount of coating, and then wipe it away. Slot die does the opposite. It applies the exact amount to the substrate. Everything the pump delivers is applied to the substrate – there is no waste.

Other methods – such as reverse roll, knife over roll, and comma coating – use a device to wipe away excess coating leaving just the thickness desired. In this scenario you’re requiring a blade or bar to be positioned2 microns away from a substrate. “That’s almost impossible,” Zwierlein said. Take a look at the photo of the human hair above and you’ll see what he means.

2. Extremely Accurate

Accuracy is based on the amount of material you want to put down, how close you are, and how uniform you want it to be. Zwierlein explains that you might be able to achieve 2 microns with other methods, but you can’t match the accuracy of slot die.

With other coating methods the gap set for the blade or the bar is fixed and the substrate and coating fluid pass through it. If the substrate thickness varies, the thickness will vary. “The substrate you coat on is never that flat,” he said.

The Important Attributes of Slot Die Coating

A number of attributes need to be present to help slot die deliver on its promise. These attributes result in significant benefits over traditional methods in terms of functionality and cost savings.

1. Precision pre-metered fluid delivery

2. Extremely flat and straight die surfaces

3. High-precision backing roll

4. Accurate and precise positioning of die to the substrate

5. Contamination-free environment

Industries for Slot Die Coating

Slot die is becoming increasingly necessary in a number of industries. Here are just a few specific applications:

Micro-electronics: Flat panel displays, thin circuits.

Batteries and capacitors: Lithium-ion battery electrodes, multilayer ceramic capacitors.

Barrier films: In food and medical packages, liquid film coatings are being applied to food coating.

Solar photovoltaic: Solar cells require thin coatings.

Slot Die Coater Design Software

Medical diagnostics: Chemistries and other solutions need to be accurately applied. Variations in thickness can result in variations in results.

Transdermal and oral pharmaceuticals: The more accurate you coat the transdermal, the more accurate the dosage.

Now let’s take a specific look at two types of slot die coating that can deliver for these applications:

Stripe Coating

Stripe coating is the preferred method when you are producing a narrow strip with exposed foil along one or both edges, in battery and capacitor applications for example.

Some requirements for good stripe coating include:

Uniform Coating Thickness

Proper cavity design is essential. You need proper die shim thickness for optimized die pressure; that produces the right uniformity for cross web production.

Accurate Width Control and Good Edge Quality

The shim sets width — it looks like a comb. Accurate shim design and fabrication is important to maintain the proper alignment. A die vacuum is used to fine-tune the width. The die vacuum also ensures there is no saw tooth or waviness.

Patch Coating

With patch coating, we’re expanding on the issues that make stripe coating desirable. It’s required when an uncoated substrate is required around the full perimeter of a coated part, not just on two sides or one side.

For example, on a touch screen or an LCD screen, you may have a grid of circuitry that requires leads to be exposed on the bottom and/or the sides. Transdermal patches require patches to be cut out of adhesives, and you don’t want to apply the medicine beyond the patch area.

Some requirements for good patch coating include:

Good Machine Direction Edges

The coating edges must be continuous, consistent and sharp.

Good Leading Edge

There can be no heavy build-up at the start of the patch. Accurate and repeatable timing is important – this is why it’s desirable to move the fluid, and not the machine. (Scott describes this method in the audio interview.)

Slot Die Coater Design Kits

Good Trailing Edge

The trailing edge should be straight and clean, no feathers or drip lines.

Uniform Coating Thickness Throughout Patch

Slot Die Coater Design Machine

Minimal variability is essential.

Here’s a graphic of a patch to illustrate some of the terms from above:

Slot Die Coating is a Huge Advantage for the Right Industries

As we noted earlier, industries such as electronics, medical devices and pharmaceutical keeping raising the bar. Converters looking to meet tighter tolerances are finding yesterday’s traditional extrusion dies can’t keep pace with the new normal.

If you’re in these uber-competitive industries, slot die coating can be the answer you’re looking for. And since “profitable” is always in vogue, it’s an advancement that will be welcomed with open arms.

Choose the right methodology for your next coating project.

Slot Die Coating (Extrusion Coating) Technology

nTact’s Slot Die Coating systems and technology allows for efficient, high performance spinless coating for applications such as flat panel displays (including LCD, OLED, flexible, and others), photovoltaic panels (such as CIGS, CdTe, OPV, and others), Solid State Lighting (OLED and LED), and various Organic and Printed Electronic applications such as RFID, Polymer Batteries, Sensors and others.

Advantages and features of nTact’s Slot Die Coating Technology include:

- Able to Coat Organic or Inorganic Liquids on flexible or rigid substrates

- Excellent coating uniformity (typically ±3% or better)

- Capable of coating a wide range of process materials: high and low viscosity fluids

- Deposit a wide range of thicknesses: from 20nm to >150μm

- High efficiency / high material utilization: typically 95% process material utilization

- Technology proven scalable from small R&D to large panel, high volume/mass production

- Systems available from R&D to large systems for production of panels over 2,000mm wide

- Highly reliable and robust process: up to 95% yields in high volume production environments

- High throughput (low TACT) processing

- Size of the system footprint is relatively small compared to competing technology platforms

- Technology applicable to roll-to-roll processing

Film Thickness Uniformity of Slot Die Coated HIL

Coated with nTact Coating System

200nm HIL, 1.6% Uniformity on 6×6” substrates*

* Optimized process and HIL formulation